OEM Manufacturer Cast Iron Non Return Valve - WCB CL300 PN80 Valve Body – Fuyang Bonly

OEM Manufacturer Cast Iron Non Return Valve - WCB CL300 PN80 Valve Body – Fuyang Bonly Detail:

Part Details:

1.Product Name: WCB CL300 PN80 Valve Body

2.Casting Process: Lost wax casting, investment casting, precision casting, water glass casting, silica sol casting and machining.

3.Material: Low-Alloy steel, Carbon cast steel, Stainless steel, Heat resistant Stainless steel, Alloy steel, Carbon steel, Ductile iron, Grey cast iron, Anti-wear cast iron, High chromium cast iron.

4.Material Standard: ASTM, AISI, DIN, BS, JIS, NF, AS, AAR, ISO, GB, etc.

5.Max Size: 800 mm.

6.Trade Item: FOB Ningbo or Shanghai, China.

7.Lead Time: 35-45 days(Details as per order quantity).

8.Software for Drawings: JPG, PDF, Auto CAD, Solid works, ProE, etc.

9.Heat Treatment: High Frequency Quenching, Medium Frequency Quenching, Carburizing and Quenching, Oil Quenching, Water Quenching, Gas quenching, Normalizing, Tempering, Annealing, etc

10.Machining Capacity: CNC machining center, lathe, milling machine, drilling machine, boring machine, grinding machine and outsourcing with our audited machining suppliers as per drawing specification.

11.Surface Treatment: Cold/ Hot Zn plating, blackening treatment, Cr plating, powder coating, Anti-rust paint, Surface Paint, Coated Anti-Rust Water, Anti-Rust Oil, etc

12.Inspection: Implement with destructive and non-destructive tests, including chemical analysis, dimensional inspection, mechanical properties test, metallographic observe, hardness test. We also co-work with international third-party testing labs to make sure all our customers’ requirements are fulfilled.

13.Packing: Wood carton, fumigation or plywood box, metal box or according to customers’ requirement.

14.Quality System Certificate: ISO 9001, ISO 14001, OHSAS 18001.

15.Service Area: Performance in the industries of Agricultural Equipment, Mineral Processing, Mining Equipment, Oil & Gas Industry, Ground Engaging & Heavy Equipment, Automobile Industry, Railway Industry, Ship Building Industry, Cement Industry, Power Industry, etc.

16.Key products: Valve shell, Valve, Support frame of the Excavator, Shot blasting machine lining plate, Shot blasting machine blade, Shot blasting machine nut, Grate Bars & Plates, Crusher & Shredder Parts, Wear Resistant Parts, Hydraulic Fittings, Valve & Pump Parts, Bucket Teeth & Adapters, and other casting parts.

Welcome to contact us if there is any project of casting part!

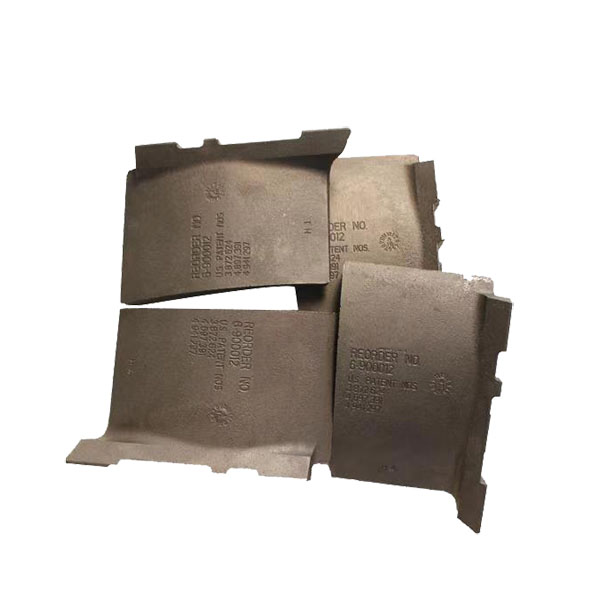

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for OEM Manufacturer Cast Iron Non Return Valve - WCB CL300 PN80 Valve Body – Fuyang Bonly , The product will supply to all over the world, such as: Sudan, Lahore, Egypt, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly