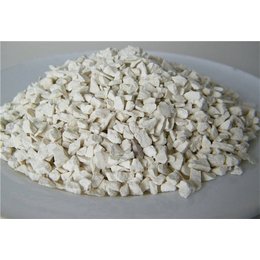

Foundry sand is used as a granular refractory material for molding sand and core sand in foundry production. In the case of using clay as a molding sand bond, for every ton of qualified castings produced, it is necessary to add 1 ton of new sand. Therefore, a largest amount of foundry sand is used in sand casting production.

Foundry sand is used as a granular refractory material for molding sand and core sand in foundry production. In the case of using clay as a molding sand bond, for every ton of qualified castings produced, it is necessary to add 1 ton of new sand. Therefore, a largest amount of foundry sand is used in sand casting production.

In the 17th century, China used silica sand as a molding material to make castings such as clocks, mirrors, pots and artillery. However, most of thoses sand was clay-containing natural silica sand, namely mountain sand and river sand, which had better plasticity and could be directly used to manufacture casting molds and cores. After the castings enter industrial mass production, especially after the mechanization of modeling, the uniformity of the clay-containing natural silica sand is poor, and the quality of the molding sand is difficult to control, which cannot meet the process requirements. Therefore, a sand plant was started to deal with the natural silica sand by Scrubing, selecting to get a variety of alternative silica sand. Besides, artificial silica sand is also made by crushing silica. At the same time, it also expands the application and development of various non-silicon resin sand modeling and core-making processes, and puts forward higher requirements for the quality of casting sand, such as less fine powder, smaller specific limit, and low acid consumption. As such, some countries that lack high-quality sand sources for the size of the sand have also developed silica sand flotation technology to improve the grade and quality of the silica sand.

In the 17th century, China used silica sand as a molding material to make castings such as clocks, mirrors, pots and artillery. However, most of thoses sand was clay-containing natural silica sand, namely mountain sand and river sand, which had better plasticity and could be directly used to manufacture casting molds and cores. After the castings enter industrial mass production, especially after the mechanization of modeling, the uniformity of the clay-containing natural silica sand is poor, and the quality of the molding sand is difficult to control, which cannot meet the process requirements. Therefore, a sand plant was started to deal with the natural silica sand by Scrubing, selecting to get a variety of alternative silica sand. Besides, artificial silica sand is also made by crushing silica. At the same time, it also expands the application and development of various non-silicon resin sand modeling and core-making processes, and puts forward higher requirements for the quality of casting sand, such as less fine powder, smaller specific limit, and low acid consumption. As such, some countries that lack high-quality sand sources for the size of the sand have also developed silica sand flotation technology to improve the grade and quality of the silica sand.

Foundry sand should meet the following requirements: ① higher purity and cleanliness, taking silica sand as an example, sand for cast iron requires SiO2 content above 90%, sintered cast steel parts requires SiO2 content above 97%; ② high fire resistance Degree and thermal stability; ③ Appropriate particle shape and particle composition; ④ Not easily doped by liquid metal; ⑤ Cheap and easy to obtain.

Foundry sand should meet the following requirements: ① higher purity and cleanliness, taking silica sand as an example, sand for cast iron requires SiO2 content above 90%, sintered cast steel parts requires SiO2 content above 97%; ② high fire resistance Degree and thermal stability; ③ Appropriate particle shape and particle composition; ④ Not easily doped by liquid metal; ⑤ Cheap and easy to obtain.

Since 1951, China has conducted a census of the foundry sand resources in succession, but it is mainly near main transportation lines and major industrial cities. In Zhelimeng, Inner Mongolia, the natural silica sand reserves amount to hundreds of millions of tons, and its particle shape is close to a circle, and the SiO2 content is about 90%, which is very suitable for industrial casting. The sea sand of Jinjiang, Dongshan, Fujian, the SiO2 content is 94 ~ 98%. There are a large number of Quaternary river and lake sedimentary silica sands in Duchang, Xingzi, Yongxiu County, Jiangxi Province. The SiO2 content is about 90%. It contains rich and fragile weathered sandstone in Guangzhou and Hunan. Its SiO 2 content is above 96%, which can be used for low iron content, less alkaline oxides, uniform particle size.

Since 1951, China has conducted a census of the foundry sand resources in succession, but it is mainly near main transportation lines and major industrial cities. In Zhelimeng, Inner Mongolia, the natural silica sand reserves amount to hundreds of millions of tons, and its particle shape is close to a circle, and the SiO2 content is about 90%, which is very suitable for industrial casting. The sea sand of Jinjiang, Dongshan, Fujian, the SiO2 content is 94 ~ 98%. There are a large number of Quaternary river and lake sedimentary silica sands in Duchang, Xingzi, Yongxiu County, Jiangxi Province. The SiO2 content is about 90%. It contains rich and fragile weathered sandstone in Guangzhou and Hunan. Its SiO 2 content is above 96%, which can be used for low iron content, less alkaline oxides, uniform particle size.

Post time: May-05-2020